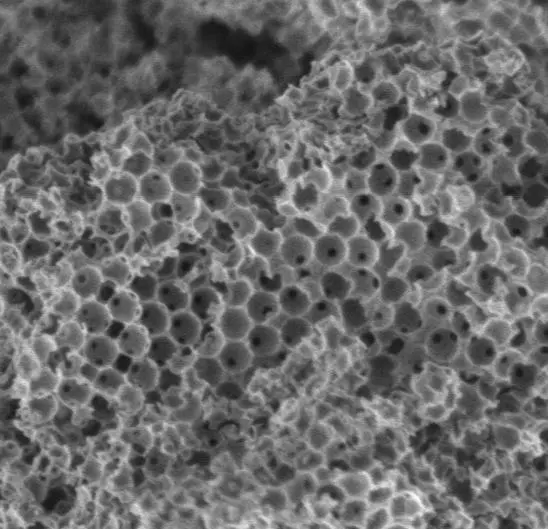

The sponge-like material is a new type of ultra-efficient catalyst for turning complex molecules into raw materials.

"Our bio-inspired approach looks to nature's catalysts – enzymes – to develop a powerful and precise way of performing multiple reactions in a set sequence. It's like having a nanoscale production line for chemical reactions – all housed in one, tiny and super-efficient catalyst particle", says co-lead investigator Professor Karen Wilson.

The sponge-like catalyst is micron sized and highly porous. When molecules are fed into the sponge, they undergo a chemical reaction in the large pores and then make their way into the smaller pores, where a second chemical reaction takes place. The process is not only cheap, but can make use of low-grade ingredients that would otherwise be destined for the scrapheap.

Among those is cooking oil, which currently needs to be cleaned thoroughly in an energy-intensive process to rid if of its contaminants before it can be turned into biodiesel.

The researchers say that in its current form, the catalyst can turn these types of low-grade feedstocks into low-carbon biodiesel using basically just a large container, along with some gentle heating and stirring. With further work, the technology could be adapted to produce jet fuel from agricultural waste, rubber tires or algae.

From here, the researchers are working to scale up the process for larger output, with an eye on commercialization.

"Our new catalysts can help us get the full value of resources that would ordinarily go to waste – from rancid used cooking oil to rice husks and vegetable peelings – to advance the circular economy. And by radically boosting efficiency, they could help us significantly reduce environmental pollution from chemical manufacturing and bring us closer to the green chemistry revolution", spune co-investigatorul profesor Adam Lee.